I. First, Understand: Why Is an ENGINE MOUNT So Important?

An ENGINE MOUNT (officially called an engine suspension bracket) is the “elastic hub” connecting the engine to the vehicle frame. This critical component serves three non-negotiable functions for vehicle performance:

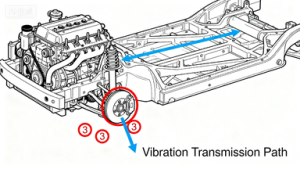

- Shock Absorption & Noise Reduction: The ENGINE MOUNT absorbs 30-50 decibels of engine vibration through its elastic structure, preventing resonance from transmitting to the cockpit (similar to a sponge pad under a table cushioning phone vibrations);

- Fixation & Protection: A high-quality ENGINE MOUNT supports the engine’s weight (80-200 kg), cushions the impact of road bumps on the engine, and prevents expensive component displacement or damage;

- NVH Performance Optimization: The ENGINE MOUNT directly affects vehicle quietness and driving quality. A worn or mismatched ENGINE MOUNT can cause severe idle vibration, acceleration noise, and even affect transmission stability.

II. 4 Core Steps for Efficient ENGINE MOUNT Selection (with Image Guidelines)

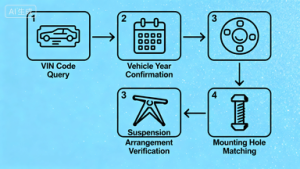

Step 1: Confirm ENGINE MOUNT Compatibility First – Avoid “Uninstallable” Mistakes

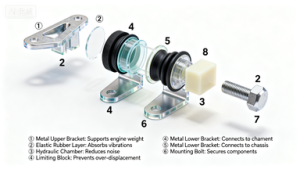

Compatibility is the foundation of choosing the right ENGINE MOUNT. Even a high-performance ENGINE MOUNT will fail if it doesn’t fit your vehicle:

- Precise Vehicle Matching: Use the VIN code to query original equipment manufacturer (OEM) ENGINE MOUNT specifications (suspension points may have changed for facelifted models after 2012, requiring special verification). Prioritize products marked “OEM-compatible ENGINE MOUNT” to avoid risks of mixing incompatible aftermarket parts;

- Verify ENGINE MOUNT Suspension Arrangement: Passenger cars mostly use 3-point ENGINE MOUNTs (excellent anti-torsional vibration performance), SUVs/commercial vehicles may use 4-point ENGINE MOUNTs (high stability), and heavy-duty vehicles often use 5-point ENGINE MOUNTs. Ensure the arrangement matches the original ENGINE MOUNT configuration;

- Check ENGINE MOUNT Mounting Holes: The bolt hole spacing and installation angle of the ENGINE MOUNT’s metal bracket must match exactly; otherwise, it will cause uneven stress on the ENGINE MOUNT and shorten its service life.

Step 2: Choose the Right ENGINE MOUNT Type Based on Needs – Material Determines Performance Ceiling

The type of ENGINE MOUNT directly impacts driving comfort and durability. Select based on your vehicle class and usage scenarios:

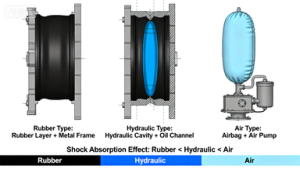

| ENGINE MOUNT Type | Material/Structure | Core Features | Application Scenarios | Reference Price Range (Per Unit) |

|---|---|---|---|---|

| Rubber ENGINE MOUNT | Pure rubber + metal frame | Simple structure, low cost, prone to hardening at high frequencies | Economy cars, budget-conscious users | $70-$210 (Aftermarket) |

| Hydraulic ENGINE MOUNT | Rubber cavity + hydraulic oil | 50% improved shock absorption, suppresses low-frequency vibration | Mid-to-high-end models, users pursuing quietness | $140-$420 (OEM) |

| Air Suspension ENGINE MOUNT | Rubber airbag + air pump | Actively adjusts stiffness for ultimate comfort | Luxury cars, high-performance vehicles | $420-$700 (OEM) |

Step 3: Don’t Ignore Key ENGINE MOUNT Parameters – They Determine Usage Experience

Technical parameters are the “hidden indicators” of a reliable ENGINE MOUNT. Focus on these three core metrics:

- ENGINE MOUNT Natural Frequency: Must satisfy fi < 2fIDLE (fi = ENGINE MOUNT natural frequency, fIDLE = idle excitation frequency) and avoid the 5-7Hz human-sensitive frequency range to prevent discomfort;

- ENGINE MOUNT Decoupling Rate: Prioritize an ENGINE MOUNT with a decoupling rate ≥ 85% – this ensures minimal vibration mode coupling and precise vibration isolation;

- ENGINE MOUNT Stiffness & Damping: Choose an ENGINE MOUNT with medium stiffness for daily commuting (balancing comfort and support); opt for higher stiffness for aggressive driving/heavy loads. The ENGINE MOUNT’s damping should match road conditions – high-damping ENGINE MOUNTs perform better on bumpy roads.

Step 4: Balance ENGINE MOUNT Brand & Budget – Avoid Low-Price Traps

A quality ENGINE MOUNT is an investment in vehicle longevity. Don’t sacrifice reliability for cost:

- ENGINE MOUNT Brand Selection: Prioritize trusted brands like Febi (Mercedes-compatible ENGINE MOUNTs feature traceable anti-counterfeiting codes) and OEM ENGINE MOUNTs (guaranteed fit and quality). For aftermarket ENGINE MOUNTs, confirm a warranty period of at least 1 year;

- ENGINE MOUNT Price Reference: OEM ENGINE MOUNTs cost $140-$700 per unit, while reliable aftermarket ENGINE MOUNTs range from $70-$280. Avoid ENGINE MOUNTs under $40 – these cheap rubber parts have poor temperature resistance and may crack in 6-12 months;

- ENGINE MOUNT Installation Convenience: Choose an ENGINE MOUNT with a reasonable structural design, where bolts and bushings meet universal standards to reduce installation labor costs and avoid damaging the ENGINE MOUNT during fitting.

III. Common ENGINE MOUNT Selection Misconceptions – Choose Efficiently Without Mistakes

- Misconception 1: The stiffer the ENGINE MOUNT, the better → A rigid ENGINE MOUNT (e.g., pure metal) offers no shock absorption, leading to direct vibration transmission and drastically reduced comfort;

- Misconception 2: Only focus on ENGINE MOUNT price → Cheap ENGINE MOUNTs use low-grade rubber that hardens and cracks quickly, increasing long-term replacement costs;

- Misconception 3: Ignore ENGINE MOUNT compatibility details → Even for the same vehicle model, facelifted years may change ENGINE MOUNT suspension points – always verify specific ENGINE MOUNT parameters;

- Misconception 4: Improper ENGINE MOUNT installation → Failing to torque the ENGINE MOUNT correctly or aligning its installation angle can reduce the ENGINE MOUNT’s service life by over 50%.

IV. Summary: Efficient ENGINE MOUNT Selection Formula

ENGINE MOUNT Compatibility (VIN + Suspension Arrangement) + ENGINE MOUNT Type Matching (Material) + ENGINE MOUNT Core Parameters (Frequency + Decoupling Rate) + Reliable ENGINE MOUNT Brand = The Perfect ENGINE MOUNT

Remember: There’s no need to blindly pursue high-end ENGINE MOUNTs. Hydraulic ENGINE MOUNTs offer the best cost-performance for daily commuting, while luxury/high-performance cars can upgrade to air suspension ENGINE MOUNTs. The key to choosing an ENGINE MOUNT is “precise matching” rather than “the more expensive, the better.”